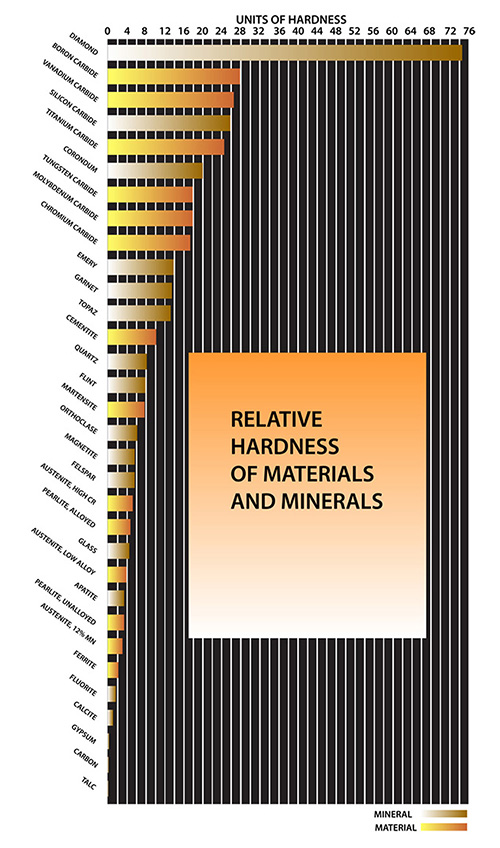

txheeb ze hardness ntawm cov ntaub ntawv thiab Minerals

-

- 1. Pob zeb diamond

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silicon carbide

- 5. Titanium carbide

- 6. Corundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10.Emery

- 11. Garnet

- 12. Topaz

- 13. Cementite

- 14. Quartz

- 15. Flint

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, Siab CR

- 21. Pearlite, Alloyed

- 22. iav

- 23. Austenite, Tsawg alloy

- 24. Apatite

- 25. Pearlite, Unalloyed

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Cov pa roj carbon

- 32. Sib

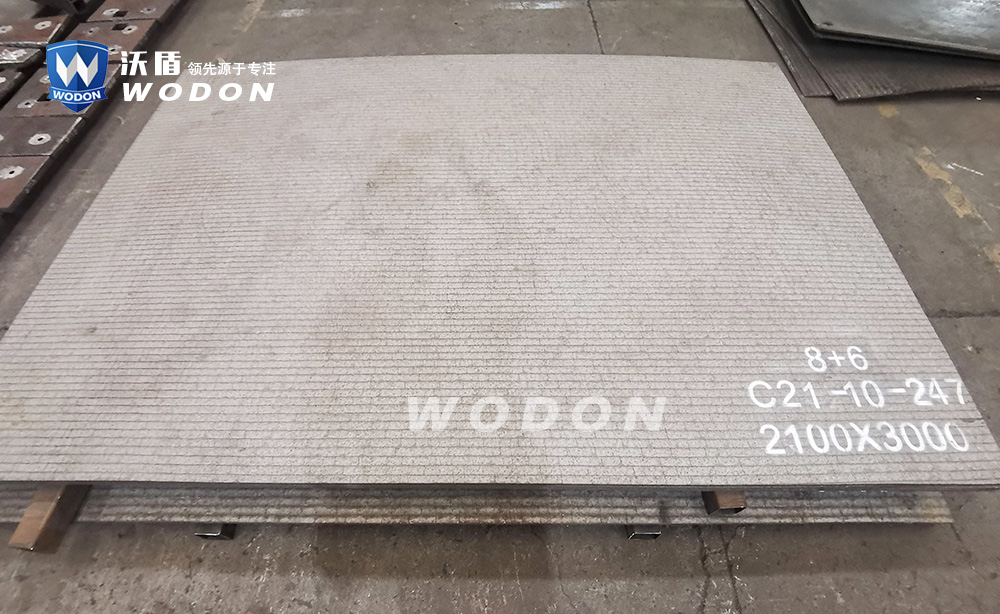

- Wodon yog tshwj xeeb hauv kev tsim Chromium carbide overlay hnav phaj, peb txais yuav submerged arc vuam technoloy uas muaj ntau Cr cov ntsiab lus xws li 25% mus rau 45%. Carbide ntim feem ntawm lub microstructure yog siab dua 50% thiab siab tshaj plaws hardness ntawm cov khoom yog HV1800. ASTM-G65 methode A yog qis dua 0.16g.

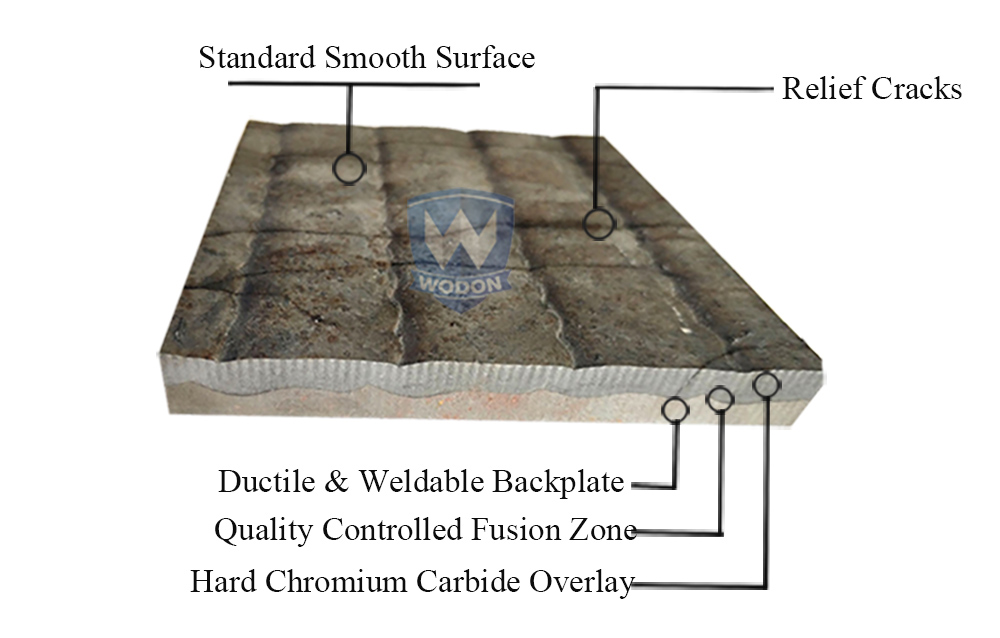

- Chromium Carbide bimetallic phaj:

- Nruab nrab /Lcarbon hlau +Abrasion resistant txheej →Chromium carbide bimetallic phaj nrog metallurgical bonding

- (Q235/Q345B + Chromium Carbide overlay →CHromium carbide bimetallic phaj los ntawm Submerged arc lossis Qhib arc vuam

- technology)

- Paub meej:

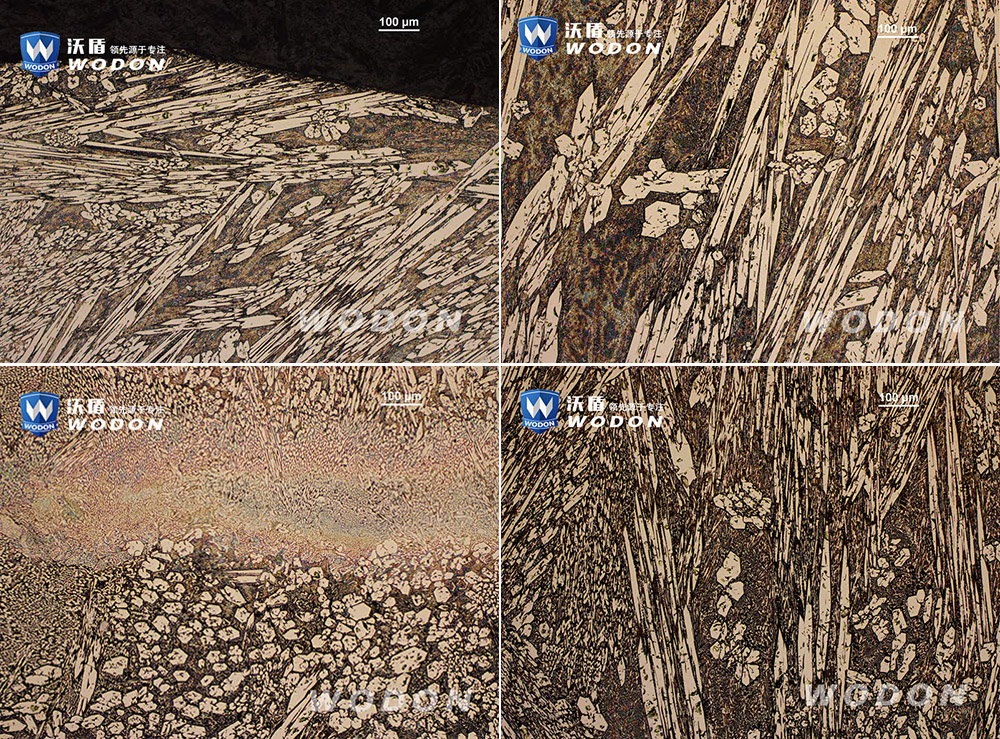

- Cov khaub ncaws hnav tiv taus muaj ntau cov chromium carbide nyuaj hais. Cov khoom no tau muab faib ua tib yam thoob plaws hauv txheej, tsim kom muaj microstructure muaj zog. Lub hardness yog HRC 58~65thiab nyob ntawm qhov overlay lub thickness.

- Cov khoom xyaw tseem ceeb ntawm Wodon phaj yog C (%): 3.0 ~6.0 thiab Cr(%): 25 ~ 45. Qhov kev faib ua tshuaj no ua rau muaj ntau ntawm Cr7C3 chrome carbide nyuaj hais. Lub micro-hardness (txog HV1800) ntawm cov khoom no thoob plaws hauv txheej yuav lav qhov hnav tsis kam tiv taus.

- Lub overlay thiab puag phaj yog metallurgical bonding. Lub overlay yuav nkag mus rau hauv lub hauv paus phaj txog 0.8 ~ 1.8 hli, nce mus txog 350 Mpa hauv peb qhov kev sim.

-

- WD1200 coj phajtuaj yeem siv rau kev puas tsuaj loj heevtions.

- * Chromium carbide overlay hnav resistant phaj

- * Los ntawm submerged arc vuam tshuab

- * Tshuaj muaj pes tsawg leeg: C: 3.0-6.0% Cr: 25-45%

- * Chromium carbide Cr7C3 ntim feem txog 50%

- * Lub thickness ntawm hnav resistant txheej tuaj yeem ncav cuag li 50 hli

- * Kub tiv taus mus txog 600 ° C

- * Lager qauv coj resistant cheeb tsam 1400 * 3000mm, 1400 * 3500mm, 2100 * 3500mm

- * Zoo dua flatness nrog du nto

- * Hardness: HRC58-65(650-720 HV)

- Cov phaj no tau siv dav hauv Mining, Cement, Fais fab, Coal, Chaw nres nkoj, Cua turbines thiab metallurgical kev lag luam.

-

Post lub sij hawm: Sep-27-2021