Vim li cas peb cov phaj hnav muaj qhov hnav zoo li no?

1. Cov tshuaj lom neeg muaj pes tsawg leeg yog qhov tseem ceeb.

Cov khoom xyaw tseem ceeb ntawm Wodon daim hlau yog C(%): 3.0-5.0 thiab Cr(%): 25-40.

Qhov kev faib ua tshuaj no ua rau muaj ntau ntawm Cr7C3 chrome carbide nyuaj hais. Micro-hardness (txog HV1800)ntawm cov nocov khoom thoob plaws hauv txheej yuav lav qhov hnav tsis kam tiv thaiv super.

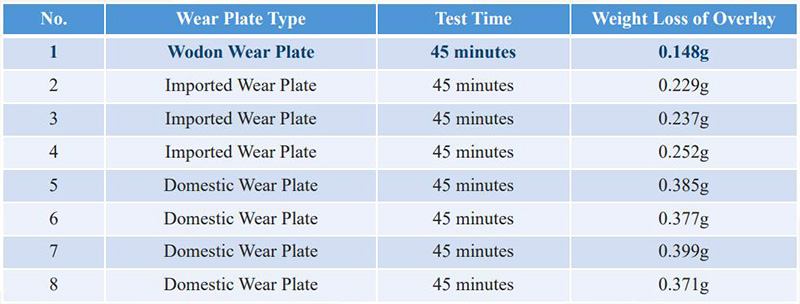

Kev Xeem Ua Haujlwm:

Cov khoom siv kuaj: Quartz xuab zeb roj hmab logabrasion xeem tshuab.

Cov xwm txheej: 1. Xaiv cov qauv zoo tib yam rau cov khoom sib txawv thiab cov neeg tsim cov phaj, thiab muab tso raunyob rau hauv tib yam hnav ua haujlwm nyob rau hauv peb cov khoom siv kuaj.

2.45 feeb rau txhua qhov qauv

45 feeb rau txhua qhov qauv

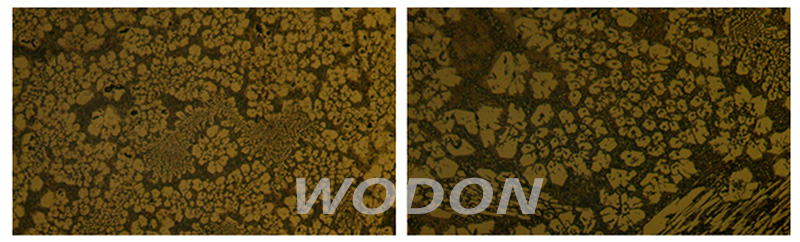

2. Chromium carbide microstructure

Kev hnav tsis kam ntawm cov phaj hnav feem ntau nyob ntawm qhov hardness, zoo, qhov loj, qhov ntau thiab kev faib tawm ntawm chromiumcarbide nyuaj hais.

Raws li koj tuaj yeem tshawb xyuas ntawm daim duab, cov carbide (Cr7C3) ntim feem ntawm lub microstructure yog siab dua 50%.

3. Bonding lub zog ntawm lub overlay thiab puag phaj.

Lub overlay thiab lub hauv paus phaj yog kev sib raug zoo heev. Lub overlay yuav nkag mus rau hauv lub hauv paus phaj txog 0.8mm-1.8mm, ncav cuagmus txog 350Mpa hauv peb qhov kev sim.

Post lub sij hawm: Aug-16-2021