WD-M3 Smooth nto

Smooth nto

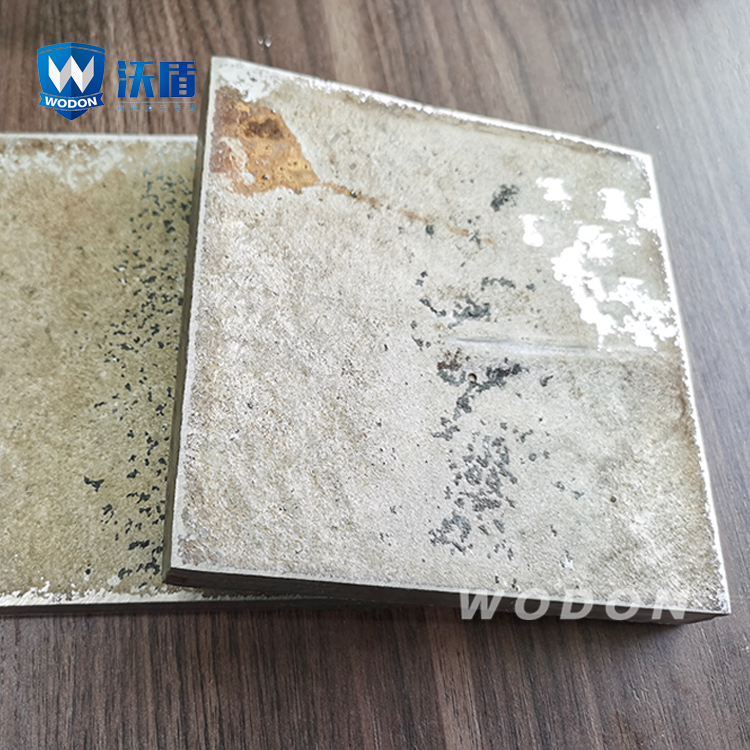

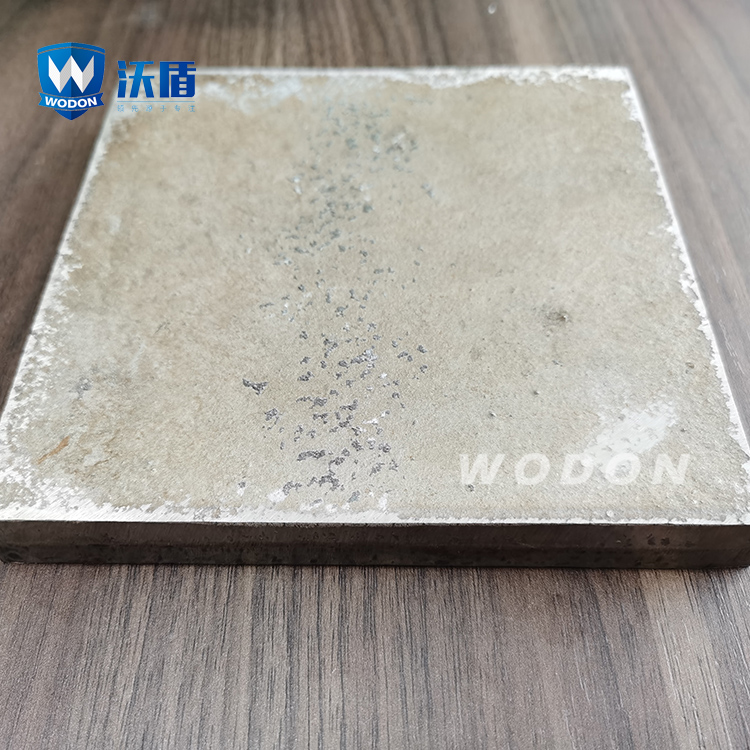

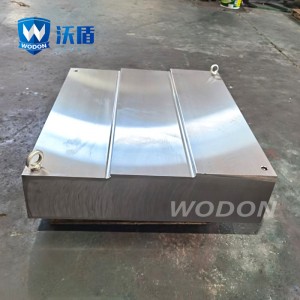

Chromium Carbide Overlay Phaj

ADVANTAGE:

* Smooth nto, ib zaug dhau overlay, Tsis nto weld hlaws

* Ua raws microstructure thiab hardness mus rau fusion kab

* Tsawg kev sib txhuam co-efficient

* Zoo heev abrasion thiab cuam tshuam resistant zog

* Ua haujlwm kub <600℃

* Yeem nyob rau hauv tshwj xeeb tsis-magnetic overlay

* Muaj nyob rau hauv zeb thiab pre-polished nto tiav

TYPICALTECHNICAL STANDARD

| Qib | Tshuaj muaj pes tsawg leeg | |||||||

|

| C | Cr | Mn | Si | B | S | P | Nb+Mo+Ti+V+W |

| WD-M3 | 2.0-5.0 Nws | 18-35 : kuv | <1.5 | <1.2 | <0.6 | <0.033 | <0.033 | <1.5 |

| WD-M7 | 2.0-5.0 Nws | 18-28 | <1.5 | <1.2 | <0.4 | <0.033 | <0.033 | 7-10 |

| Cov ntsiab lus tseem ceeb | WD-M3 | WD-M7 |

| Cov khoom siv hauv paus | q235 ib | q235 ib |

| Main alloy nyuaj theem | Chromium carbide | Chromium carbide + Composite carbide |

| Primary carbide ntim (%) | > 37 | > 37 |

| Overlay Hardness los ntawm HV (HRC) | 670 (58) . | 670 (58) . |

| Roj hmab log abrasion xeem nrog cov xuab zeb qhuav (g) | <0.15g | <0.14g |

| Impact abrasion test (g) | <0.10g | <0.08g |

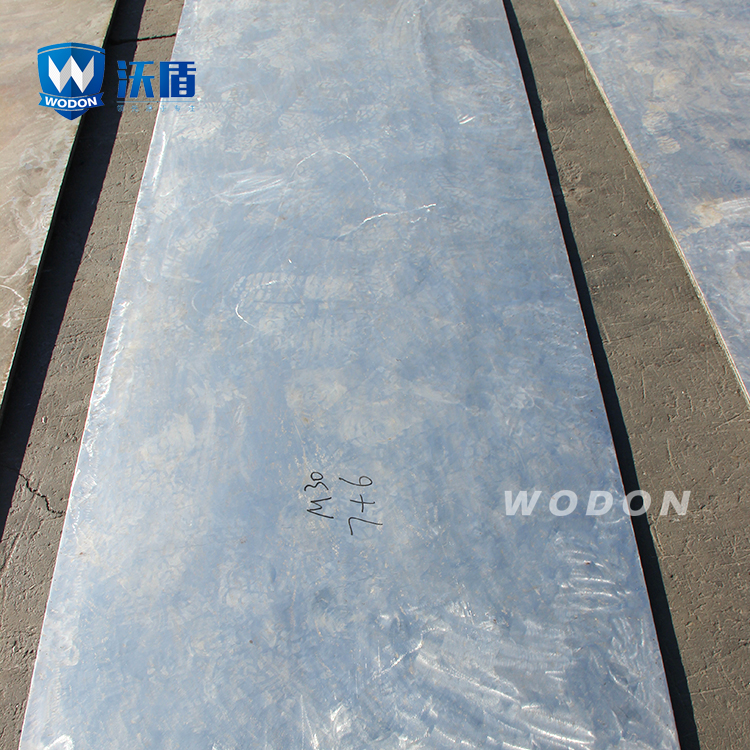

| Standard thickness (mm) | 5/5, 6/7, 8/9, 10/11, 12/11, 17/11 | 17/11, 20/11, 24/13 |

| Standard phaj loj (mm) | 1000 * 3000, 600 * 3000 | 600 * 3000 hli |

| Pom zoo daim ntawv thov | Kev puas tsuaj | Kev puas tsuaj heev |